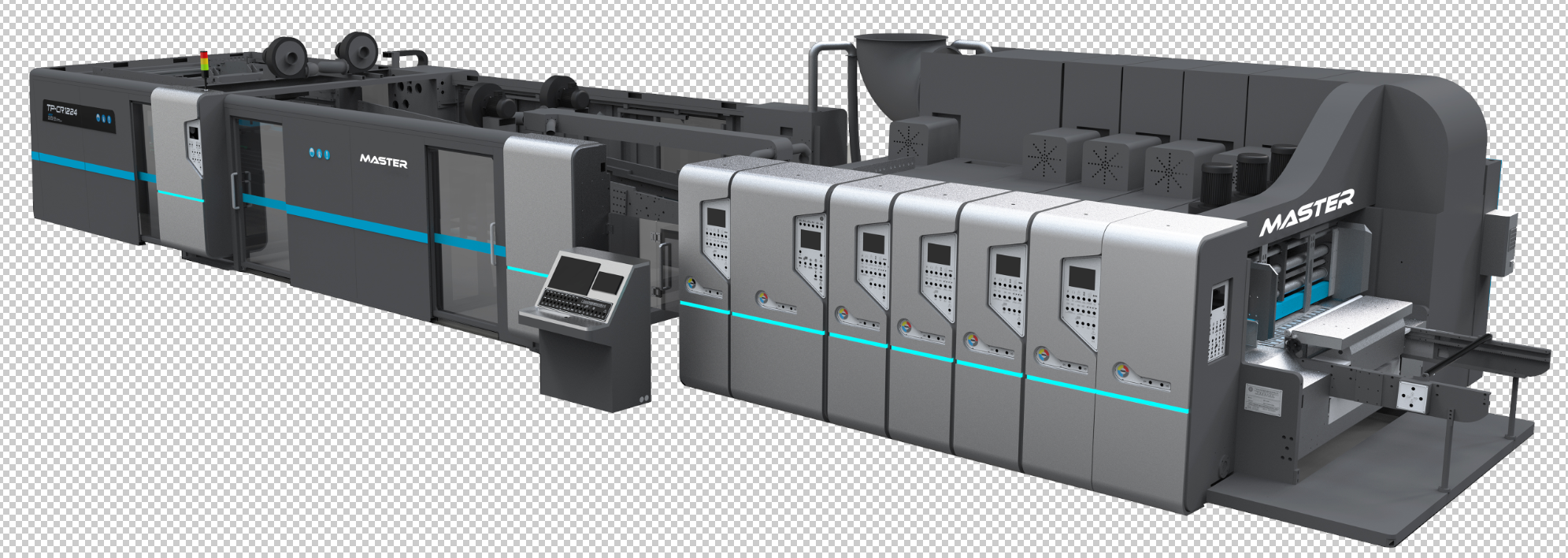

Features

- Flexo Folder Gluer Inline control, adopts independent Central Computer (with Keyboard & Mouse) match with PLC and Touch Screen in each Unit for automatic operation, all operation function can achieve automatic adjustment by data input or Order Management system, Easy to Operate, Fast Order Change, and can connect with ERP System.

- All the Electronic Components are adopted International First Brand, Stable and Durable, the Main Control Box equipped with Industrial Constant Air Conditioner, Each Unit equipped with Anti-dust, Air Fan to ensure reliable and durable working performance.

- All the Main Transmission Gears adopt special imported material, carburizing and quenching, precision grinding, long life time and durable. With Oil Balance and Automatic Circle Lubrication System.

- Vacuum Transfer, widely applicable for different cardboard, the suction box will be combined together to ensure same pressure when machine is closed, which makes more accurate printing, and save adjusting time and cardboard.

- Internal video surveillance production, can check the cardboard transmit in any moment.

- Multi-sets of Germany Bosch Rexroth servo motor coordinate action. Single stacks quantities can be from 10~30 cartons, and 25 stacks per minute.

- Adopts USA Valco Spray gluing system and equipped with wheel to wheel gluing system.

- Japanese Nitta main conveyor belts provide stable transmission performance.

- Easily match with Pre Feeder and Automatic Strapping Machine and Robot Palletizer or Load Former.

Technical Parameter

Feeding unit (Servo Control, Non-crush Feeding System)

- Servo Control non-crush feeder, 4 shafts transmission.

- Continuously or Skip Feeding

- Paperboard leading edge as the positioning benchmark, in line with printing, slotting, die-cutting positioning benchmark, to improving paper feeding and printing accuracy.

- High ability for feeding Bending, Wrapping and Thin cardboard.

- Fully upper suction dust remove system + brushes, dust collection tube, to remove the dust and scraps effectively.

- Anti-static Dust removing system (Optional).

- To compare with Traditional feeding rollers, non-crush feeder does not damage the strength of the cardboard, save materials.

- Improve the feeding accuracy, even running at high speed will not affect the feeding accuracy.

- Any flute type above F flute can be feed horizontally and vertically.

Printing unit (Vacuum Suction)

- Vacuum Transfer, can adjust Air Volume automatically according size of cardboard.

- Standard machine equipped with Rubber Roller, Chambered Doctor Blade is Optional.

- Chambered Doctor Blade is equipped with Fast Ink-return and Automatic Cleaning Device.

- Standard machine equipped with Normal Ceramic Roller, NOVA, ART Ceramic Roller for Optional.

- Reel Hanging Plate, Ratchet Locking Device to make sure hanging plate alignment is more accurate.

- Printing Register is Servo Control, fast and accuracy.

- Hot air and IR Device is optional.

- The suction box will be combined together to ensure same pressure when machine is closed, which makes more accurate printing, and save adjusting time and cardboard.

- Can check the cardboard transmit situation in Central Computer.

Slotting Unit (Pre Ceasing, Big Creasing, Fine Creasing, Slotting)

- 8 Shaft Transmissions, Pre-creasing, Big Creasing, Single Shaft Slotting or Pre-creasing, Creasing with Dual Slotting is Optional.

- Linear Guiding structure combined with Ball Screw for Transverse adjustment to make sure accurate knife fitting, stable movement.

- Transverse, Box Height, Gaps adopts computerized or motorized adjusted.

- Slotting Register is Servo Control, more precision.

- Elastic Corner Cutter Structure to suitable for different thickness cardboard.

- The lower corner cutter can be rotated to protect the upper corner cutter, and ensure the stitching flap can be cut off.

Die-cutting Unit

- Die-cutting Rubber Cylinder is driven by independent frequency motor for line speed compensation. And Servo control is optional.

- Register adjustment adopts servo motor dual-pole adjustable gap planetary gear with 360° precision adjustment.

- Segmented Rubber Anvil and transverse moving is ±30mm.

- With Automatic Grinding Device.

Inline Folder Gluer (Top Counter Ejector)

- Friendly HMI for operation.

- Servo Control, adopts 7 servo motors, fast speed, high accuracy, and easy to adjust.

- Gap of Upper and Lower Belts automatic control or by Order Management.

- Top-Loading Counter Ejector match with Top printing Flexo Printer. Inline Control, the main operation function adopts data input or by Order Management for automatic adjusted.

- The Max. working speed is 350 sheets/min, huge capacity, save labor cost, and greatly improve the production capacity.

- The Right & Left Belt pressure, angle can be adjusted, to ensure the carton can be conveyed synchronously and smoothly; The upper and lower matching brushes to prevent waste paper to be brought in; there are two Fans with multi-outlets to speed up the drying of printing and ensure the printing quality.

- USA Valco Gluing System, easy to operate and maintain, glue distance can be adjusted freely, save glue. And equipped with wheel to wheel glue system.

- The Right & Left Arm adopts rack and Linear Guiding Rail, to ensure precision positioning and precision adjusted, can be adjust by order management system or digital adjusted.

- The main conveyor belt adopts Japanese NITTA brand, and the deformation is small after long-term use

- R./L. Differential speed belt adopts independent Servo Control; it can follow the running of main belts synchronously, and also can adjust the speed difference freely, to ensure different size of carton to be folding more accuracy.

- The auxiliary air outlet is equipped to help cardboard falling smoothly.

- Paper Insert Arm & back move, upper & down adopts independent Servo Control, to make sure the movement is accuracy; the Press Arm adopts Servo Control, to ensure piles of carton fall evenly, and reduce vibration and Noise.

- The pile of Carton Holding Device adopts independent Servo Control; the front belts of Counter Ejector adopt independent Servo Control cooperate with push-out action, start and drain at a constant speed, and match with Carton Holding Arm, Press Arm to finished the movement of Carton Press, Falling, and Conveying evenly.

- Counter Ejector First phase belt and second phase belt are adopting Servo Control for transmission; speed is automatically changed according to front belts running.