Flexo Folder Gluer | Casemaker in China Market Status

Mar 23,2022 | MASTER

During these years of Covid 19 epidemic situation, the China market of corrugated packaging industry have been updated a lot, especially for flexo folder gluer.

If we look back on history, the offline flexo printer slotter diecutter and offline #foldergluer have been popular in these 30 years. Nowadays, Flexo folder gluer became the standard equipment at #boxfactory, which improved the process efficiency of RSC and HSC (RSC: regular slotting carton, HSC: half slotting carton) a lot, and reducing the manpower cost and space.

Many #corrugated box factories have 4~6 sets of offline flexo printer slotter diecutter (99% are top printing type, speed about 150~300 sheet/min) and 2~3 sets of offline folder gluer (up folding type, speed about 100~250 sheet/min), and some stitching machines (at the moment, stitching box is still had big market requirement, especially for TV box, AC box, Refrigerator box, etc.).

Offline #FlexoPrinterSlotterDiecutter:

Offline Folder Gluer:

The cost of traditional offline folder gluer (up folding type) is less than the inline one (down folding type), this is the main reason management prefer to buy the offline one, especially at the beginning of running the factory.

Due to the labor cost have been increased a lot and labor shortage issue (new generation is not willing to work inside the factory) in these years, and the updated local made #FFG can reach the required performance (no fish tail, and glue gap is well control, and speed is stable on 200~300 sheet/min), the management prefer to invest more money on the fully computerized inline equipment to replace few sets of offline flexo printer and folder gluer, to guarantee the stable output.

#FlexoFolderGluer | FFG | #Casemaker:

Here are benefit of inline machine:

- Saving time & space:

At offline machines, the carton box is needed to load twice (one is at feeder of printer, another is at feeder of folder gluer); and it is needed to unload twice (one is at the stacker of printer, another is at the stacker of folder gluer). The flexo printer & folder gluer (without prefeeder) is required each 15m length, and there is necessary transit space about 6m length or more depends on condition for corrugated board between two machines.

At Inline machines, the carton box is only needed to load & unload once. And there is not required space for transit the corrugated board between two machines because it’s directly connected.

- Saving labor cost:

Normally one offline printer slotter diecutter is required 5 persons (2 person on feeding the board into the machine, 1 operator, 2 person on collect the pile of board at stacker.) and same that on offline folder gluer. If make the Flexo printer inline with folder gluer then only required 5 persons, which mean saving half labor cost. And at modern plant, only 1 person to operate the #FFG if equipped with auto pre feeder to load the sheet into the machine (which save 2 person), and save another 2 person after strapping machine if using the #robot #palletizer for stacking the finished carton.

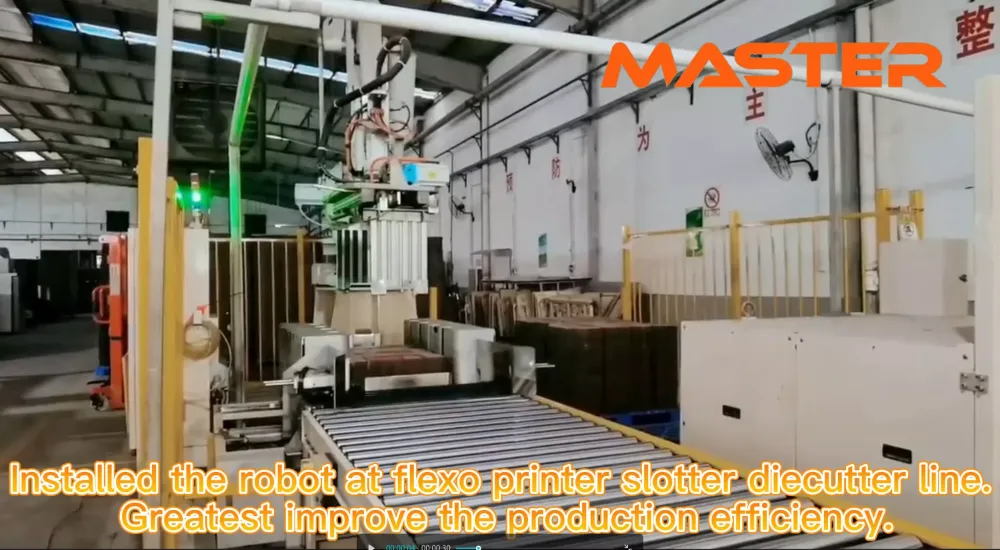

Robot Type Palletizer:

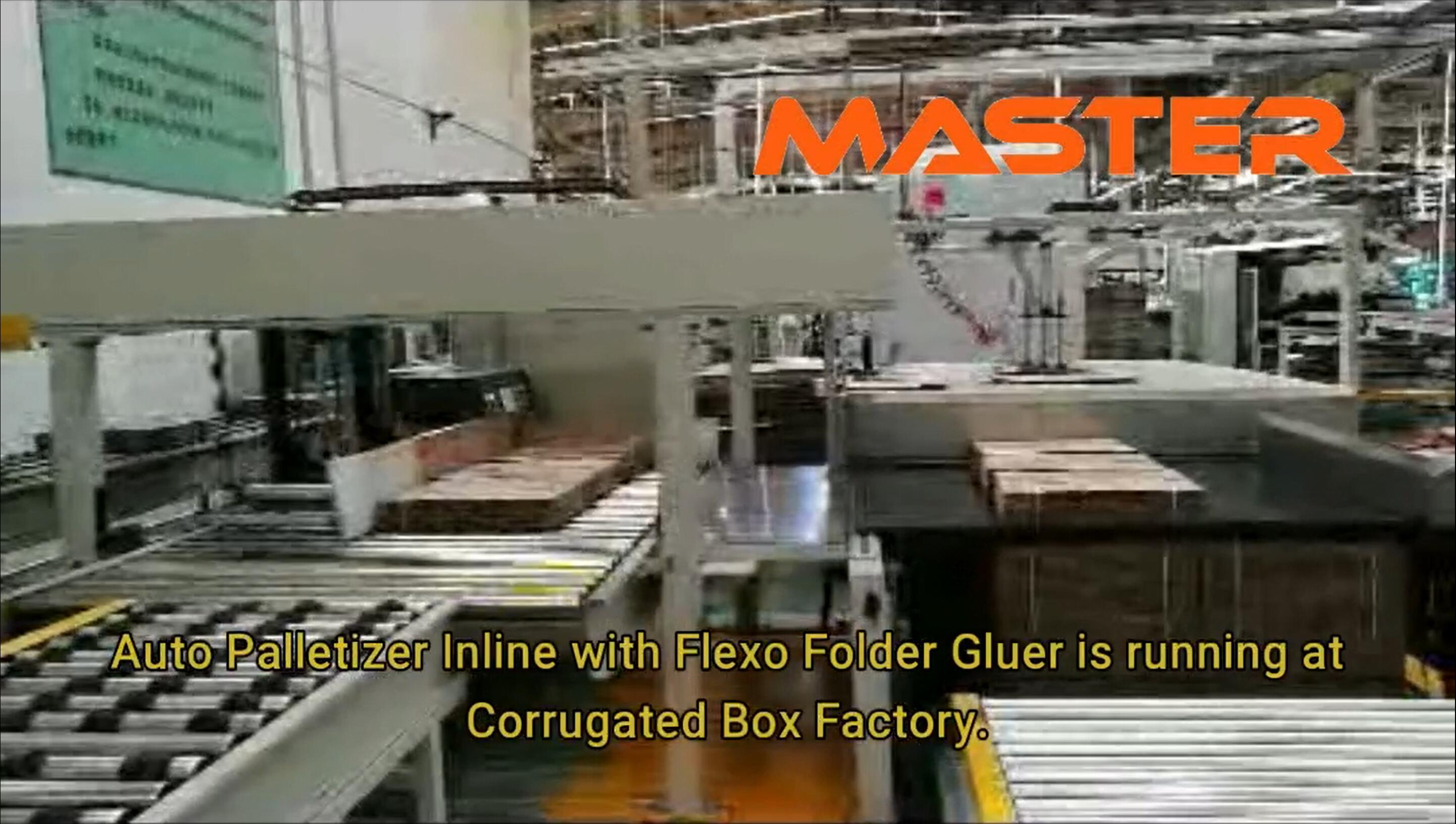

Automatic Palletizer: