Comparison Between Intelligent & Manual Slotter

Jun 08,2022 | MASTER

Comparison Between Intelligent & Manual Slotter

The slotter machine is widely used at corrugated box factory, no matter big plant or manual plant, which is helpful for making small quantity order or some special slotting size boxes.

The manual slotter (as below picture) is quite simple with low investment, but the output is small with low efficiency. The setting is needed to do manually, firstly to use the tape to measure the slotting gap based on the box size, then fix the slotting seat at roller, secondly to adjust the slotting depth, which will take few minutes. If daily have many different size of orders, it will waste too much time on setting and create small amount of output value.

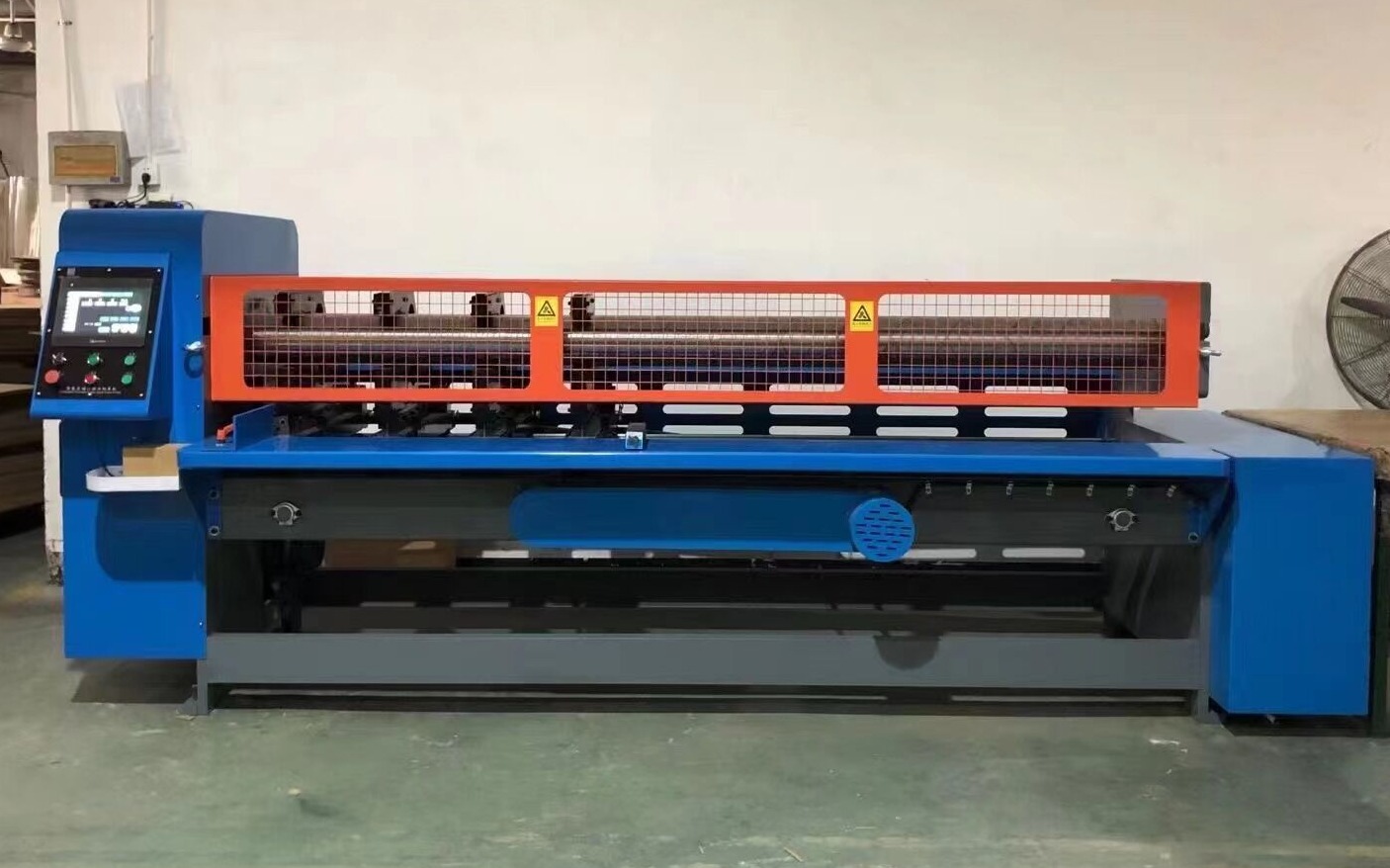

In order to improve the efficiency and create bigger amount of output value, we (#master) have developed the latest slotter, which is intelligent with fully servo control and order change in 3 seconds. The operation is friendly by touch screen or QR code gun scan which is connected with ERP system. Once the data is setting at touch screen or QR code gun scan system, the machine is automatically done the adjustment such as slotting gap, slotting depth.

And it is really saving time compared with traditional way. (3 seconds VS few minutes).

Also, our #intelligent #slotter can save order function which is easily for repeat production.

There is available for size 2.5m and 3m or special design, with the slotting depth option of 410mm or 610mm, suitable for 3ply, 5ply, 7ply (AAA) corrugated Box.

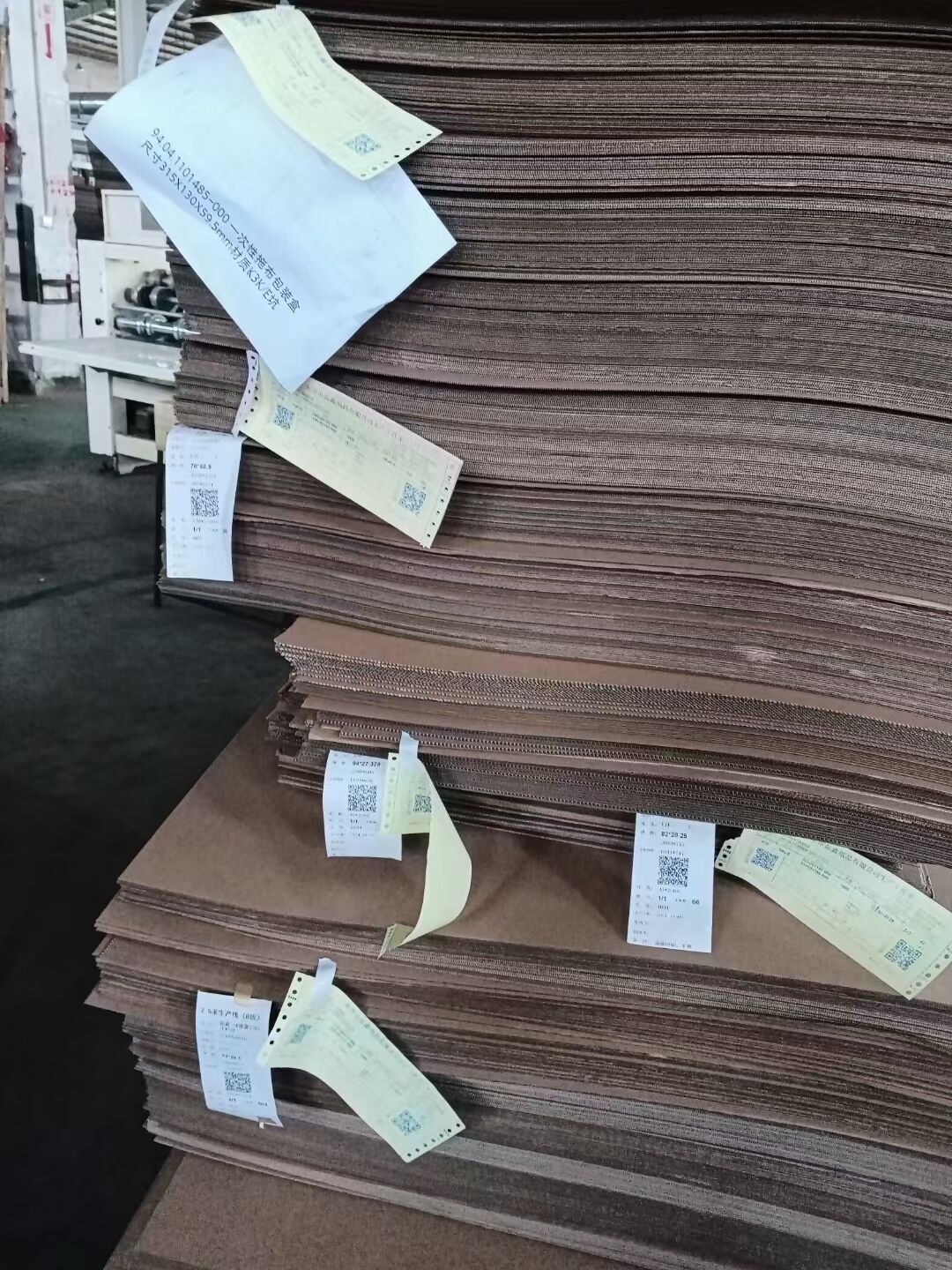

For example, if your orders type is similar to our customers as below, it will be a smart choice for you to use our intelligent slotter to create more value.

Here is the video of #IntelligentSlotter for your reference.