How to Solve the Corrugated Board Problem?

Sep 04,2022 | MASTER

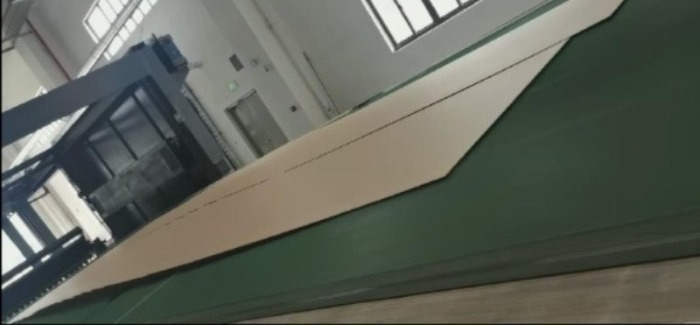

During the production of corrugated board making process, we may face the problem as below picture showed due to the paper or machine or operation issues, etc.

Here are some steps for solving this issue:

- First check whether the height of hot plate ballast bar is consistent, and the amount of glue applied is uneven or too large.

- Check whether the corrugated height is one side high and one side low at single facer. whether the overbridge wind is too strong, whether the brake is too tight, whether the gluing rubber stick, roller and squeegee wheel are applied, and whether the amount of glue is applied, and whether the small roller is adhered at the entrance of the large conveyor belt of double backer.

- The top paper is too thin and the glue is too large. Heat the top paper less and make the glue smaller. Let the cardboard bend downward and draw the wind down

- There is an obvious regular spacing between the corrugated boards. 1) First check whether the corrugated paper has wave jumping, and then check whether the scraping stick and sizing stick of the corrugated machine and glue machine are deformed, as well as the bearings at both ends. 2) Check the hot plate sail belt for slippage. Whether the vehicle speed is stable

- Reduce the amount of glue and increase the machine speed. Because the machine speed is slow and the water content of the paper is low, the imprint can not be seen at that time, but it will appear after a period of time.

It is important to have skills of operation, maintance, problem detect, solve issue, then can make the nice corrugated board.