Description:

- There is no need for a skilled master, and a novice can take up his post.

- It can reduce the harm to the intelligent workers.

- Servo motor, four knives and six lines, three seconds in place, accurate movement.

- Pre-creasing and creasing are synchronized.

- No need to adjustable positioning baffle.

- The host can adjust the next order without stop the machine.

- 600 order memory

- Digital control.

- Six axis pressing paper, paper separation will not inclined.

- Pre-creasing, creasing, and paper clamping are all controlled by motor

- Monitoring system, timely attention to paper separation, reduce scrap rate.

- The whole machine uses brand motors (Schneider servo motor, drive, PLC) with guaranteed quality.

- Patent development of operating system, more personalized and more convenient.

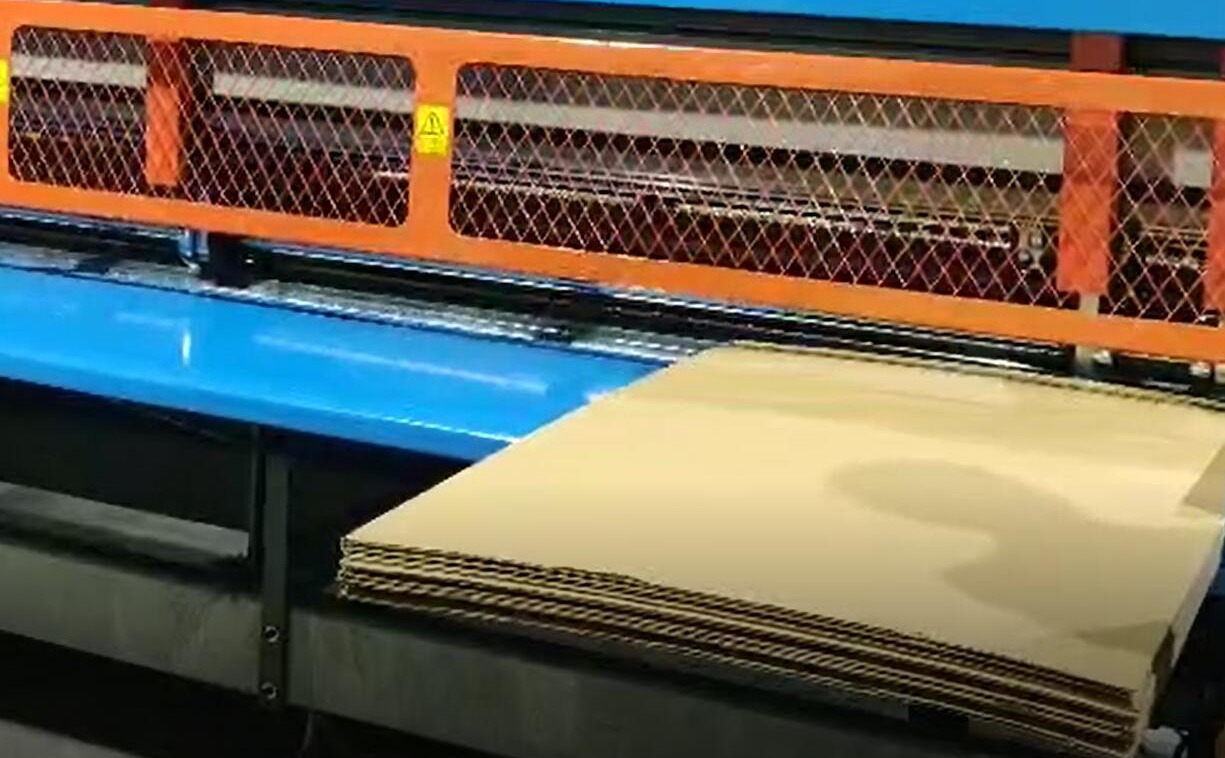

Optional Manual Feeder or Lead Edge Feeder Type:

|

Item |

Brand |

|

Model |

2546 (2500mm, 4 knives, 6 corner) (optional model 2846, 3058,3246, 3546, 3558) |

|

Working speed |

120m/min |

|

Touch screen |

Touch screen operation, simple interface, easy to operate. |

|

Cutter seat servo drive motor |

Schneider servo motor |

|

Wire wheel servo drive motor |

Schneider 400W servo motor |

|

Main drive frequency converter |

Fast drive |

|

Low voltage electrical apparatus |

Schneider series |

|

Transmission mode of main motor |

Adopt chain drive, with good stability and low noise |

|

Line pressing form |

The convex to square formula is adopted |

|

Machine overall size |

(length * width * height) 3800 * 1500 * 1900mm |

|

Main motor power |

Jiangsheng brand motor 4kw |

|

Total power |

7KW |

|

Helical rack |

The helical gear design makes the error smaller |

|

PLC |

Schneider PLC |

|

Minimum feed length |

420mm |

|

Minimum separation width |

140mm |

|

Minimum indentation spacing |

40mm |

|

Paper separation and indentation positioning accuracy |

±0.5mm |

|

Blade specification |

200*122*1.2mm |

|

Blade material |

Tungsten alloy knife |

|

Suitable board thickness |

2-12mm |

|

Servo motor. Servo drive |

Schneider |

|

PLC controller |

Schneider |

|

Feed shaft |

2400*127mm |

|

Pre pressing wheel and wire pressing wheel |

Φ148mm |

|

Crimping wheel convex line |

The customer can choose the thread wheel and convex line |

|

Bearing |

NSK, Harbin, C&U |

|

Total weight |

2200~3200KG(different model different weight) |