Main Technical

|

Max. sheet size |

1650 x 1200 mm |

|

Min. sheet size |

600 x 500 mm |

|

Max. cutting size |

1630 x 1180 mm |

|

Sheet thickness |

1-9mm |

|

Min. grip size |

10 mm |

|

Cutter height |

23.8mm |

|

Max. production speed |

6000 pieces/hour |

|

Max. operation pressure |

350 tons |

|

Required power supply |

60kw (main motor 30kw) |

|

Exterior size(L×W×H)(with platform): |

11500×5220×2440mm |

|

Net weight of machine |

38 tons |

Feeder Section:

-

The latest servo-drive and lead edge feeding type guarantees the smooth feeding of large size cardboard and improves the operation and production ability. Highly precise feeding without damaging the cardboard strength.

-

Suitable for all kinds of paper, and data setting can be adjusted on the touch screen.

-

Big size front and side baffles make cardboard at right position, providing high die-cutting precision.

-

Paper leveling device is specially designed for bent cardboard, stopping cardboard cover the front baffle.

Diecutting Section:

- Steady die-cutting performance guarantees the high precision. Strong and reliable high speed driven guarantees the smooth running of gripper bar.

- Die-cutting frame locking structure, the die-cutting steel plate is used air reducer to reduce the weight, easy control. With transducer to prevent the plate in wrong position which resulting defects brought by deflected creasing line.

- Die-cutting positioning device can realize quick locating and higher accuracy of die-cutting.

- The hardness die-cutting steel plate can be installed easily and quickly.

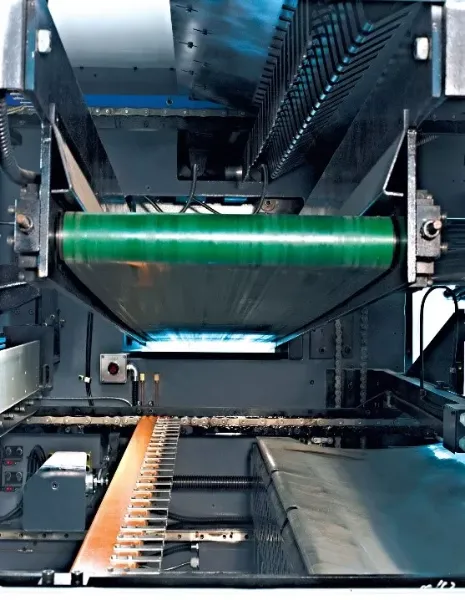

Stripping Section:

-

The quick-setting way of die is adopted; operator can finish the setting from exterior without entering the machine.

-

Male and female die can be inserted into the machine from operation side to shorten the setup time and for higher safety.

-

Upper and lower frames make the dies succeed in performance. Male and female dies can move up-an-down,making stripping more completely.

-

A plastic film is set between die-cutting section and lower frame for stopping paper swerve.

-

It can be adjusted by moving hand crank according to the size on the dies operation direction.

Knock-off Section:

- The knock-off wood mold is used to separate the grip edge and finished cardboard. The wood mold is inserted directly on the operation side, and once self-lock by cylinder.

Grip Edge Waste Remove Device:

- The grip edge waste is removed from the gripper bar and transferred out of machine on the conveyor system.

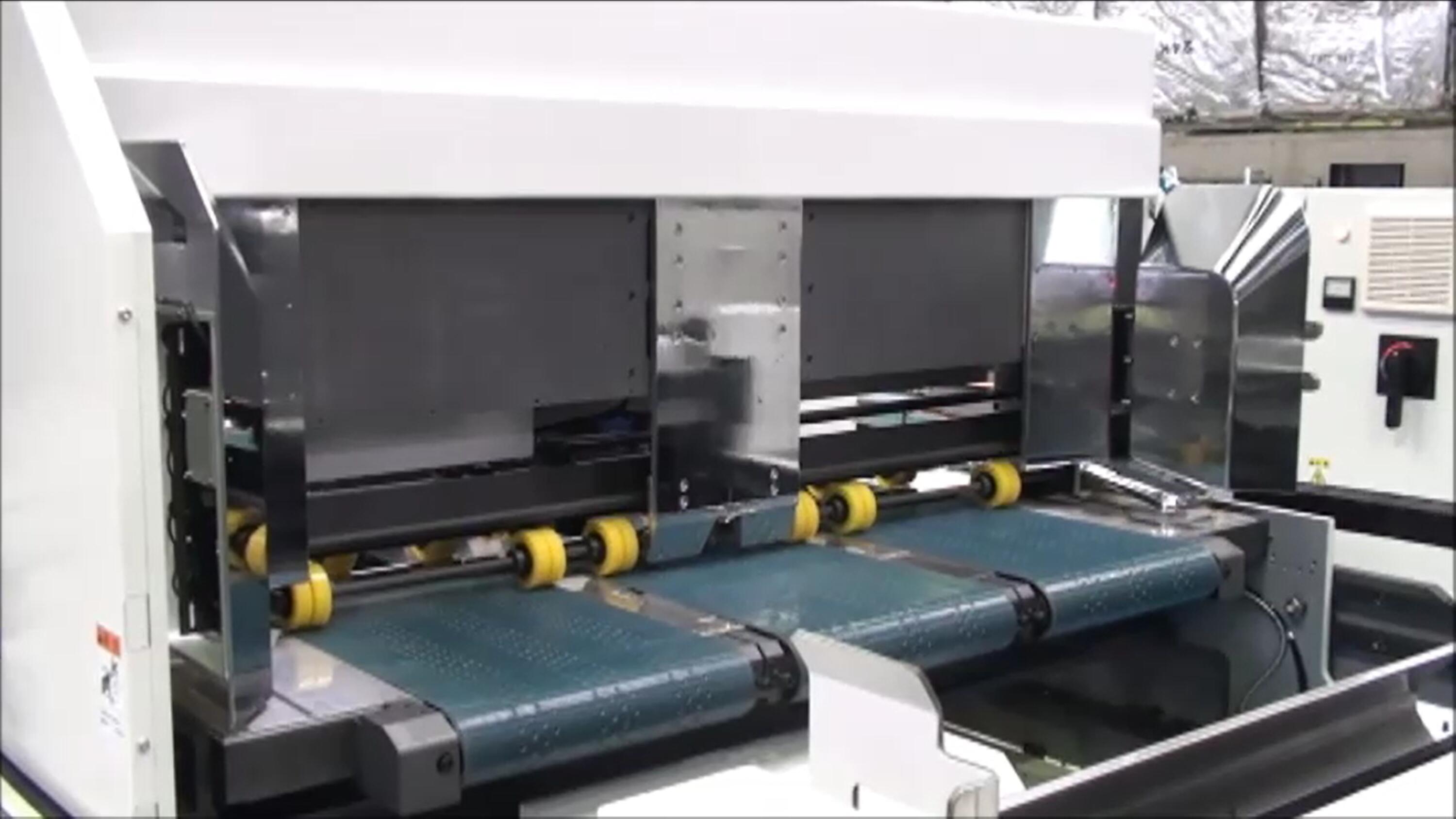

Delivery Section:

- Front and back barriers with side aligning device make receiving tidy.

- Side baffle and back barrier coordinate and can be adjusted by motor based on the sizeon productiion d irection.

- Delivery platfrom is driven by motor, easy for setting.

- Temporary receriving device controlled by servo-actuator makes delivery more simple and easy.